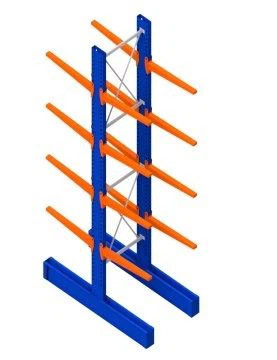

Cantilever Racking System is designed with C/C roll-formed upright column of hot-rolled coil, while arm and column are bolted connected by lifting lug.

Cantilever Racking System is designed with C/C roll-formed upright column of hot-rolled coil, while arm and column are bolted connected by lifting lug.

Brief Introduction

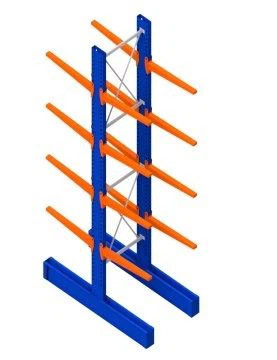

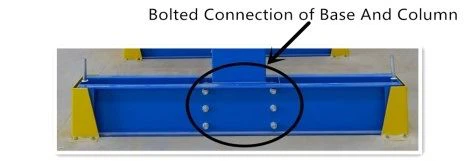

Cantilever Racking System is designed with C/C roll-formed upright column of hot-rolled coil, while arm and column are bolted connected by lifting lug. The base is a welded single unit to be bolted with column. Adjustable diagonal flats and connecting bar are designed to improve the whole stability. Both single-side and double-side bases are available to meet different storage requirements. Also, it has the advantages of flexible operation, high safety factor, and does not require a large number of warehouse managers.

Features

Cantilever Racking System can effectively improve the turnover rate and help fulfill the modern warehousing needs of low cost, low loss and high efficiency. It has sufficient load-bearing capacity, durability and high safety factor, and its surface is well protected against corrosion and rust. This racking system keeps warehouses organized, resulting in efficient operations.

More to know

1. Exceeding 6m height is available, the highest column is able to reach 10.5m;

2. Heavy loading, loading of single-arm can up to 1500kg.

3. Keep selling to Australia market more than 10 years.

4. Long and irregular material goods stored.

5. Our arm has a 2° uptilt which can make sure the arm won’t tilt down while goods placing.

6. Except from the regular size, the longest arm can last to 3m.

7. The connection of our cantilever column and arm is ingenious, it can mitigate the impact of forklift operation.

|

|

| Mitigate the Impact of Forklift Operation | Extra Long Arm |

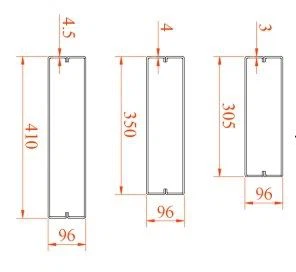

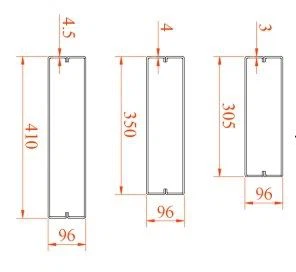

Column

Jracking heavy duty cantilever rack column is made of roll-formed C/C profile quality steel.

Section of column

Loading capacity mainly depends on column height and arm length.

Specific dimension also can be customized as request.

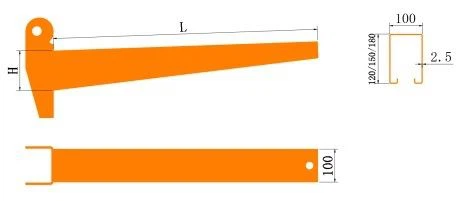

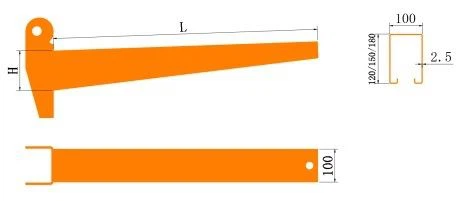

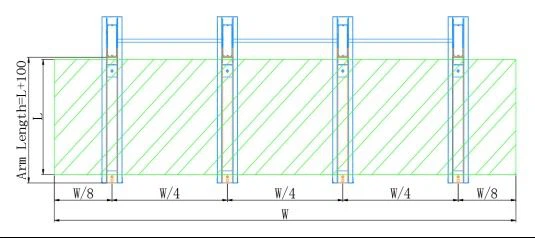

Arm

The range of loading capacity/per arm is 500kg-1500kg.

Specific dimension also can be customized as request.

| Arm | Specification | Length |

| H120 | 800-2000mm | |

| H150 | ||

| H180 |

Loading Table(Kg)

| Height/loading/length | 800 | 1000 | 1200 | 1400 | 1600 |

| H120 | 1500 | 1380 | 1020 | 750 | 570 |

| H150 | 1500 | 1500 | 1250 | 1190 | 910 |

| H180 | 1500 | 1500 | 1250 | 1250 | 1250 |

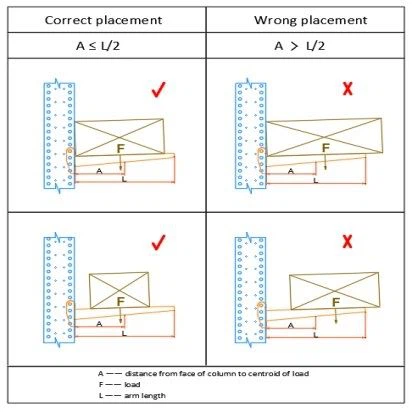

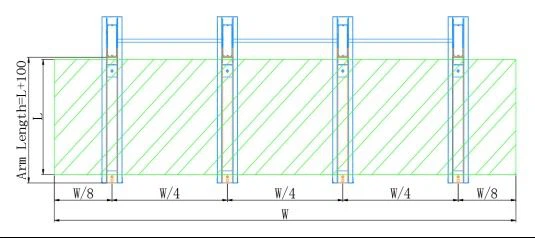

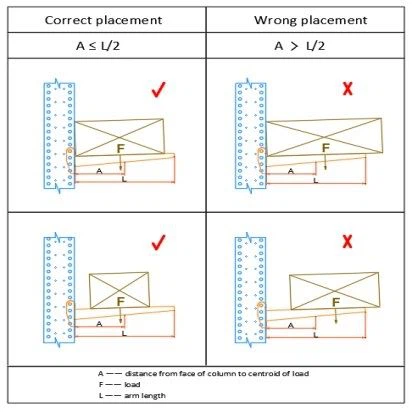

Method of Goods Placing

The effects of correct and incorrect practice are both shown in the Figure below.

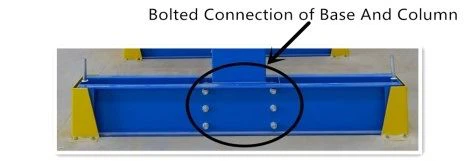

Base

Single Base and Double Base

Relationships of length between single/double base and arm are as follows:

Single Base(L)=Arm length+390mm;

Double Base(L)=Arm length*2+318mm;

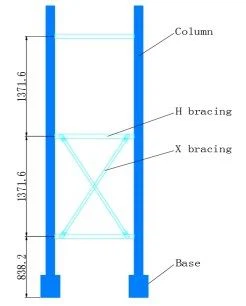

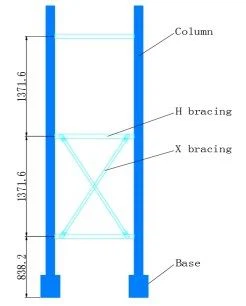

H-bracing and X-bracing

| Item | Dimension | C/C Distance |

| H-bracing | 60x30x2.5 | 500mm-2000mm |

| X-bracing | Φ32×1.5 |

C/C distance 1000, 1200,1400, 1600, 1800, 2000.

Other specific dimension also can be customized as request.

Accessories

Project Pictures

Our factory

Jracking factory delivers 80 containers per month. After receiving the order, production can be completd in 20 days.

Packing and Loading

Certificates

CUSTOMERS' SATISFACTION IS JRACKING'S ETERNAL PURSUIT